Back in the late spring of 2023, Toronto became the first city in North America to implement new standards to limit upfront embodied carbon emissions in new municipally owned buildings through the use of lower-carbon construction materials. Mandated for all City buildings (and certain private developments), the standards require that upfront embodied carbon emissions — those generated from material extraction, manufacturing, and the transportation and assembly of structural and envelope systems — be capped at 350 kgCO2e/m2. In response, local architecture firm BDP Quadrangle, which made its own commitment that 100 per cent of its projects would be net-zero carbon–ready with a targeted embodied carbon intensity (ECI) of 250 kgCO2e/m2 by 2030, assessed 44 of its already built multi-unit residential projects to understand the impacts of ECI on envelope expression, form and material selection. “We wanted to create an accessible tool box to understand and influence design decisions with regards to embodied carbon,” says architect and innovation director Michelle Xuereb.

Focused on the building envelope, the multi-month undertaking resulted in a comprehensive data set that provides architects with a tool to determine an embodied carbon budget long before shovel hits ground. Here, Xuereb shares some key considerations when devising a low-carbon, sustainable building.

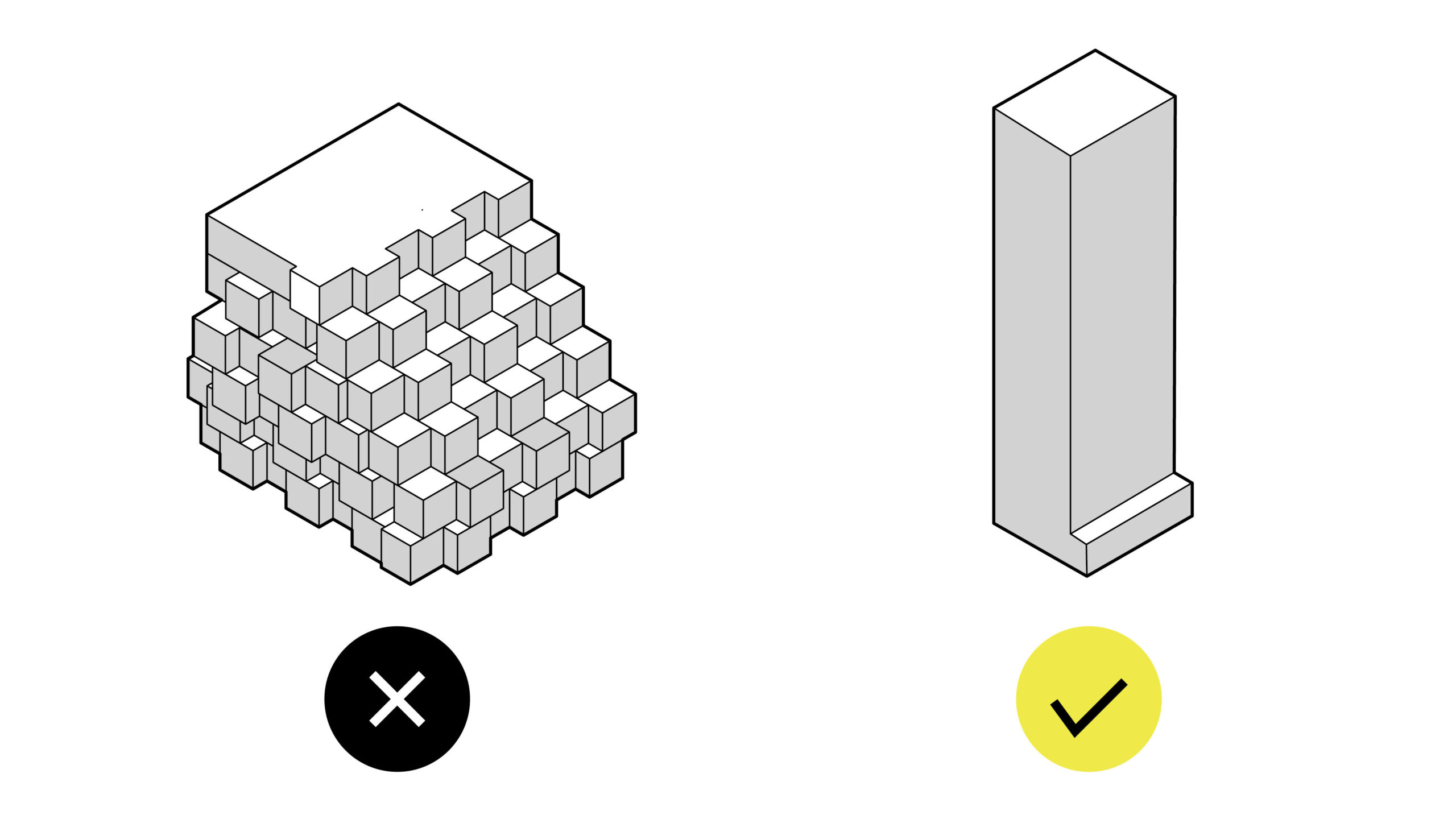

Simpler Forms > Complex Forms

BDP Quadrangle found that 23 per cent of a building’s embodied carbon is derived from its envelope, and the more complicated the design, the bigger that impact. A major factor related to this is the vertical floor area ratios (VFAR), since buildings with a lower VFAR will minimize material demands by nature of their reduced surface area.

Reconsider Glazing

The building’s window-to-wall ratios (WWR) are another big factor. The firm determined that keeping the WWR below 40 per cent means utilizing more solid wall assemblies than aluminum window wall systems, which are more carbon-intensive.

Maximize Density

Optimizing the density of a building requires a mix of unit sizes and layout efficiency. Projects that incorporate one-, two- and three-bedroom units with compact layouts and an average size of 75.4 square metres were found to be the most effective at limiting material use and distributing embodied carbon effectively.

Be Selective with Materials

When planning the envelope, materials make a difference. Aluminum systems and glass, though popular, are currently high in embodied carbon; as production processes change and become more efficient, these numbers will reduce. Until then, opting for ceramic, brick or even precast concrete can significantly reduce a building envelope’s ECI.

Toronto’s BDP Quadrangle Creates a Tool Kit for Low-Carbon Design

The local firm has developed an insightful guideline to assist architects in designing carbon-conscious buildings.