By the time the earthquake hit, 26 new homes were already built. Just 15 kilometres from the epicentre of a 7.7 magnitude tremor that devastated Mandalay in March, levelling entire city blocks across Myanmar’s second-largest city, the cluster of bamboo houses remained intact. Initially built as refuge for families displaces by the region’s ongoing civil conflict, the resilient structures offer a proof-of-concept for a new housing model that draws on inexpensive, abundantly available local material to deliver rapid, dignified and surprisingly flexible housing to one of the world’s most seismically active and windswept regions.

Developed by local architecture studio Blue Temple, the new homes form part of the firm’s ongoing Housing NOW initiative, which leverages bamboo to build low-cost housing and social infrastructure for internally displaced persons (IDPs) across the country. The crowd-founded project harnesses a prefabricated structural frame to create a range of rapidly assembled typologies, including a pre-school, orphanage, community centre and medical clinic, as well as two models of family homes. While the larger civic projects entail proportionally higher budgets, the residential buildings were constructed at a cost of just USD $1,000-$1,300 per home.

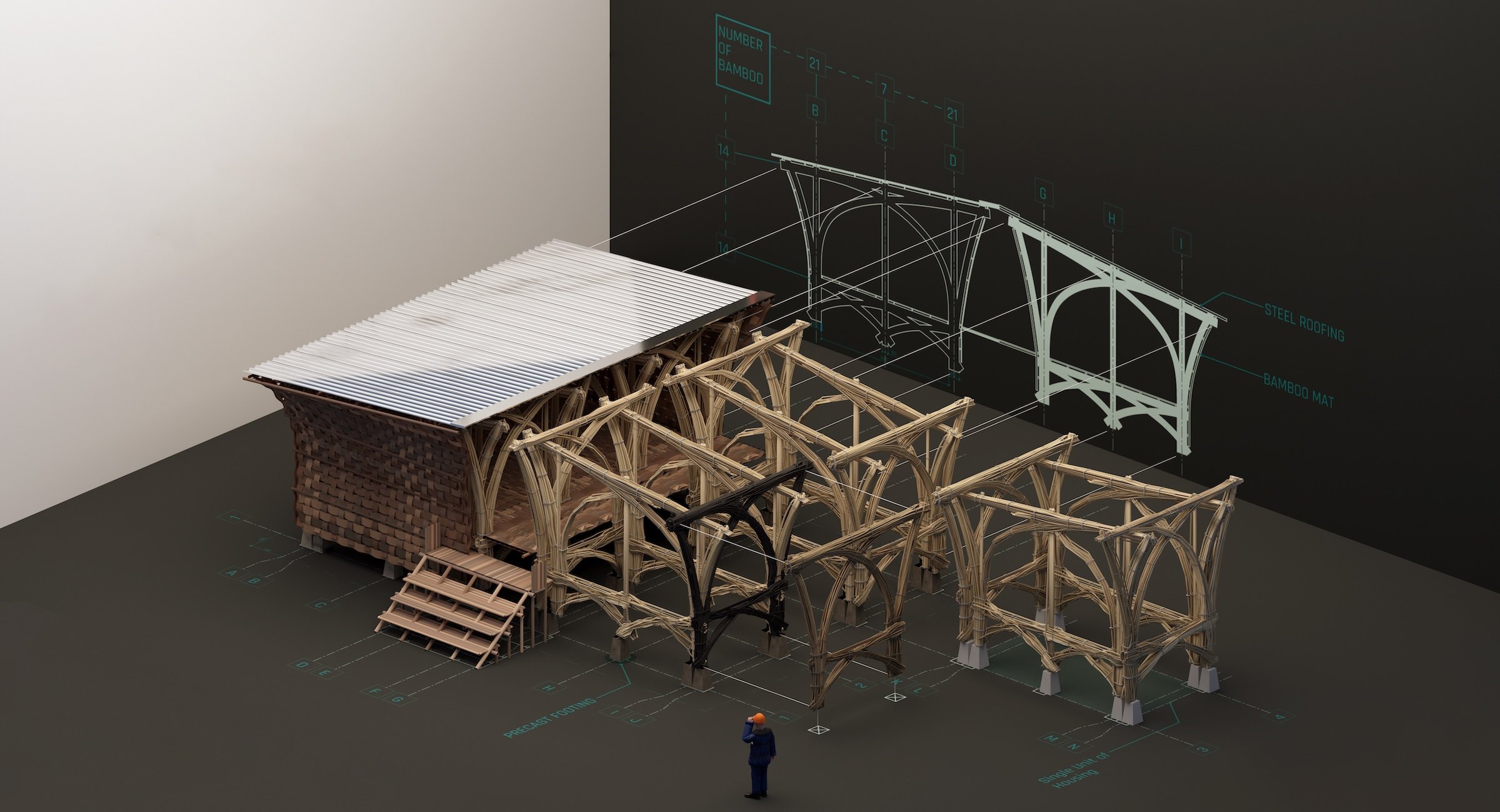

All of Housing NOW’s evolving typologies take advantage of Blue Temple’s innovative prefabricated bamboo structural frame system. Assembled at a local production hub in the city of Bago, the frame uses bundles of interlocking small-diameter bamboo — which is typically considered a waste material — held together by inexpensive pneumatic steel strapping.

To ensure durability and protection from termites and fungi, the bamboo is first chemically treated with ecologically sensitive boron-based preservatives. Designed using a computationally developed geometric system that distributes seismic loads and wind pressures, the elegantly vaulted interlocking forms are the building blocks of a versatile system that allows significant internal variance in floor plans.

The prefabricated frames can be quickly deployed and scaled as needed, with excess building materials stored in the Bago factory for emergency dispatch. A customized low-bed trailer is used to transport the bamboo frames across the whole of Myanmar’s rugged landscape, including emote locations marked by low-hanging electric cables and mud roads.

On site, the prefab system facilitates a simplified construction process, allowing the families themselves to customize the form and fit out of their home. Once the concrete footings are installed, the build requires only simple hardware, meaning that residents themselves can participate in — and even lead — the process.

The materials used for the roofs, floors and walls vary depending on local conditions, available materials and individual resident preferences. In some contexts, elegant woven bamboo facades frame the buildings, though a range of other materials — including wood, stucco and corrugated steel plates — can also be applied. Since the Housing NOW project’s launch in 2019, 75 buildings have been completed, including the cluster of 26 homes outside Mandalay, a clinic in Kachin State, as well as a pre-school, orphanage and homes in Yangon Region.

To further streamline and democratize the process, Housing NOW has also published a DIY Bamboo Manual, allowing communities across Myanmar to undertake construction projects with locally available materials and tools. Moreover, Blue Temple is developing a toolkit for upgrading self-built homes by guiding families and carpenters with technical expertise and structural advice.

In Myanmar, such strategies respond to a unique set of local challenges. Alongside the chronic risk of earthquakes and tropical cyclones, the country is home to an growing population of IDPs amidst the Rohingya genocide and a wide range of related conflicts and insurgencies. In this difficult context, Housing NOW has emerged as both vernacular and innovation.

In Myanmar, Resilient Housing for the Price of a Smartphone

Blue Temple’s Housing NOW transforms small-diameter bamboo bundles into a durable and abundant low-cost building material.